Services

Whether it's commercial or domestic, A1 Service - Thermal Imaging provide a national service for all aspects of electrical testing, appliance risk assessment, inspections, tagging and reporting. Australian legislation require all businesses carry out a duty of care by complying with the Occupational Health & Safety Act. A full comprehensive report is given after every test and your records are maintained so an annual test and check can be automatically scheduled in giving you one less task to worry about each year.

Thermal Imaging

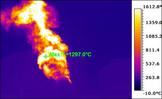

A1 Service Infrared Thermal Image Scanning is a preventative maintenance process which assists in the reduction of emergency maintenance costs on electrical and mechanical equipment and is an excellent condition monitoring tool used to carry out non destructive testing. While the equipment is online and running under full load, you are able to monitor temperatures and thermal patterns. It allows for early detection of faults indicated by a rise in temperature. Your guideline would be the operating temperature limits that most mechanical equipment allows.

Infrared Thermal Imaging can be used on a wide variety of electrical and mechanical equipment unlike most other test methods. Faults detected at an early stage can be investigated or repaired as part of your routine maintenance program or planned outage basis, thus reducing the need for unnecessary shutdowns.

Infrared Thermal Imaging is an electronic technique which quite literally allows us to see thermal energy. A1 Service - Thermal Imaging has recognised Infrared Thermal Imaging as one of the most versatile and effective condition monitoring tools available today. It can help in detecting equipment failure and you can plan corrective action before costly shutdowns, equipment damage, by using the services of A1 Service - Thermal Imaging.

Rollover the image below to see the unforeseen fault in these electrical components.

|

|

|

|

Power Quality Monitoring

|

A1 Service is able to provide power quality monitoring, which is the process of gathering,analising and interpreting raw measurement data into useful information.

This information can then be used to improve the power qualitiy and performance of an electrical system, saving you both time and money. |

Testing & Tagging

|

A1 Service - Thermal Imaging is an authorised reseller of Seaward Testing and Tagging Equipment, so you can be assured you have quality personnel using quality equipment.

|

|

As an employer you have a duty of care to provide a safe workplace for all employees as part of the Occupational Health & Safety (OH&S) Goverment Legislation. A1 Service offers a full comprehensive testing and tagging service in accordance with the AS3760:2003 regulations.

Testing and tagging your appliances, electrical equipment and machinery reduces your risk by minimising the potential harm of electricity in your domestic or commercial environment. Using an advanced test and tagging service, we will keep you, your staff, your customers and your assets safe from the ever potential dangers of using faulty equipment.

|

|

To ensure you are complying with the OH&S standards, A1 Service offers fixed periodic contracts so you don't have to remember when your last test and tag service was. A1 Service will take care of that for you and contact you when your testing is due for renewal.

|

A full comprehensive report will be given which complies with all your OH&S regulations.

RCD Testing

|

An RCD is an electrical safety device that helps to prevent electrical injuries and fatalities. An RCD monitors the flow of electricity and is designed to immediately switch the electricity off when electricity is 'leaking' to earth is detected at a level harmful to a person using electronic equipment.

A1 Service tests RCD's to ensure the safety of your electrical equipment according to the Australian Standards AS/NZS 3760 RCd's need to be tested every 12 months to two years. All RCD's in a workplace environment must be tested and records kept. |

Ground Penetrating Radar

|

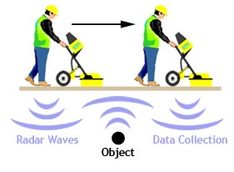

A1 Service uses state of the art ground penetrating radar systems to assist in the detection of abnormalities under the surface, thereby reducung the need for more destructive measures in locating a problem.

Some of the uses of ground penetrating radar are

|

High Temperature Scanning

Reporting

The report produced is an important part in the survey or inspection process. With that in mind, we aim to provide you a full, comprehensive, easy to understand report clearly identifying all the hazards in your environment.

Each item thermally imaged, photographed, inspected or tested is clearly documented showing all then necessary requirements for you to have peace of mind knowing you have a safe environment and you are adhering to your legal OH&S requirements. All faults are documented in the report with a unique rating system showing the severity of the fault.